Document Control Software for Manufacturing: Streamlining Processes and Ensuring Compliance

In the fast-paced world of manufacturing, efficient document control is crucial for maintaining quality, ensuring compliance with industry standards, and improving overall operational efficiency. Document control software plays a vital role in streamlining processes, reducing errors, and enhancing collaboration among teams.

The Benefits of Document Control Software in Manufacturing

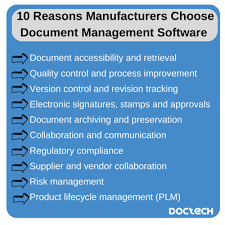

Document control software offers a range of benefits for manufacturing companies:

- Centralized Document Repository: Document control software provides a centralized repository for storing all documents related to manufacturing processes, including work instructions, standard operating procedures (SOPs), quality manuals, and more.

- Version Control: With version control features, manufacturers can track changes to documents over time, ensuring that employees are always working with the most up-to-date information.

- Access Control: Document control software allows companies to define access levels and permissions for different users, ensuring that sensitive information is only accessible to authorized personnel.

- Audit Trails: By maintaining detailed audit trails of document revisions and approvals, manufacturers can easily track document history and demonstrate compliance during audits.

- Collaboration Tools: Many document control software solutions offer collaboration tools such as commenting features and real-time editing capabilities, enabling teams to work together more effectively.

Ensuring Compliance with Industry Regulations

In the highly regulated manufacturing industry, compliance with standards such as ISO 9001, FDA regulations, or industry-specific requirements is essential. Document control software helps manufacturers ensure compliance by:

- Automating Workflows: Automated workflows streamline document review and approval processes, reducing the risk of errors and ensuring that documents meet regulatory requirements.

- Document Change Management: Manufacturers can easily manage document changes through automated change notifications and approvals, maintaining compliance with regulatory standards.

- Auditing Capabilities: Robust auditing features enable manufacturers to generate reports on document history, approvals, and revisions—facilitating compliance audits.

The Future of Document Control in Manufacturing

As manufacturing processes become increasingly complex and globalized, the need for robust document control solutions will continue to grow. Advanced technologies such as artificial intelligence (AI) and machine learning are being integrated into document control software to further enhance efficiency and accuracy in managing manufacturing documentation.

Manufacturers who invest in modern document control software will not only streamline their operations but also stay ahead of regulatory requirements and market demands. By leveraging the power of technology to manage their documents effectively, manufacturing companies can drive innovation, improve quality assurance processes, and achieve greater success in today’s competitive landscape.

8 Essential Tips for Choosing and Implementing Document Control Software in Manufacturing

- Choose a document control software that is specifically designed for the manufacturing industry to ensure it meets your unique needs.

- Ensure the software complies with industry regulations such as ISO standards to maintain quality and compliance.

- Implement user permissions and access controls to restrict unauthorized personnel from viewing or editing sensitive documents.

- Regularly update and review your document control processes to adapt to changing regulations and best practices.

- Integrate the document control software with other systems like ERP for seamless data flow and improved efficiency.

- Provide adequate training to employees on how to use the document control software effectively.

- Establish version control mechanisms to track changes, revisions, and approvals of documents accurately.

- Regularly back up your documents in secure locations to prevent data loss in case of system failures or disasters.

Choose a document control software that is specifically designed for the manufacturing industry to ensure it meets your unique needs.

When selecting document control software for manufacturing, it is essential to opt for a solution specifically tailored to the industry’s requirements. By choosing software designed with the nuances of manufacturing in mind, companies can ensure that the system aligns with their unique needs and processes. Industry-specific document control software offers features and functionalities that cater to manufacturing workflows, compliance standards, and quality management practices, ultimately enhancing efficiency, accuracy, and regulatory adherence within the manufacturing environment.

Ensure the software complies with industry regulations such as ISO standards to maintain quality and compliance.

To ensure optimal document control in manufacturing processes, it is essential to select software that aligns with industry regulations, including ISO standards. By choosing software that complies with these stringent guidelines, manufacturers can uphold quality standards, enhance compliance efforts, and streamline operations effectively. Adhering to ISO standards not only ensures consistency and accuracy in document management but also demonstrates a commitment to meeting industry best practices, ultimately leading to improved efficiency and regulatory compliance within the manufacturing environment.

Implement user permissions and access controls to restrict unauthorized personnel from viewing or editing sensitive documents.

Implementing user permissions and access controls in document control software for manufacturing is essential to safeguard sensitive information and maintain data integrity. By setting up granular permissions, companies can restrict unauthorized personnel from viewing or editing critical documents, ensuring that only authorized individuals have access to confidential data. This not only enhances security but also helps in compliance with industry regulations by controlling who can make changes to important manufacturing documents. Effective user permissions and access controls play a key role in preventing data breaches and ensuring that sensitive information remains protected within the manufacturing environment.

Regularly update and review your document control processes to adapt to changing regulations and best practices.

It is crucial for manufacturing companies to regularly update and review their document control processes to adapt to evolving regulations and best practices. By staying proactive in monitoring changes in industry standards and compliance requirements, organizations can ensure that their document control software remains effective in managing documentation accurately and efficiently. This practice not only enhances regulatory compliance but also strengthens overall operational performance, enabling manufacturers to stay ahead of the curve in a dynamic business environment.

Integrate the document control software with other systems like ERP for seamless data flow and improved efficiency.

Integrating document control software with other systems like ERP in manufacturing is a strategic tip that can significantly enhance operational efficiency. By seamlessly connecting document management processes with enterprise resource planning systems, manufacturers can ensure a smooth flow of data across different functions, departments, and workflows. This integration not only reduces manual data entry and duplication but also improves accuracy, consistency, and accessibility of information throughout the organization. Ultimately, the synergy between document control software and ERP systems empowers manufacturing companies to optimize their processes, make informed decisions, and drive overall productivity to new heights.

Provide adequate training to employees on how to use the document control software effectively.

To maximize the benefits of document control software in manufacturing, it is essential to provide adequate training to employees on how to use the software effectively. By offering comprehensive training sessions, workshops, and resources, companies can ensure that their employees understand the features and functionalities of the document control software. Proper training not only improves user proficiency but also enhances collaboration, reduces errors, and promotes compliance with industry regulations. Investing in employee training demonstrates a commitment to leveraging technology for operational excellence and empowers staff to make the most of the document control software to streamline processes and drive productivity in manufacturing operations.

Establish version control mechanisms to track changes, revisions, and approvals of documents accurately.

Establishing robust version control mechanisms is essential when utilizing document control software for manufacturing. By implementing effective tracking of changes, revisions, and approvals of documents, manufacturers can ensure accuracy and reliability in their documentation processes. Version control not only helps in maintaining the integrity of documents but also enables teams to work collaboratively with confidence, knowing they are referencing the most up-to-date information. This practice streamlines workflows, reduces errors, and enhances overall operational efficiency in the manufacturing environment.

Regularly back up your documents in secure locations to prevent data loss in case of system failures or disasters.

Regularly backing up your documents in secure locations is a crucial tip when utilizing document control software for manufacturing. By ensuring that your data is safely stored in multiple locations, you can mitigate the risk of data loss in the event of system failures or unforeseen disasters. This proactive approach not only safeguards your valuable manufacturing documents but also provides peace of mind knowing that your critical information is protected and easily recoverable when needed.